Additionally, if the development team is pulled from another project, the opportunity cost of the delayed project must be factored into the incremental cost of the new feature. They are always composed of variable costs, which are the costs that fluctuate with production volume. If a reduced price is established for a special order, then it’s critical that the revenue received from the special order at least covers the incremental costs. A very simple example would be a factory making widgets where it takes one employee an hour to make a widget. As a simple figure, the incremental cost of a widget would be the wages for the employee for an hour plus the cost of the materials needed to produce a widget.

Leveraging Incremental Cost for Better Business Decisions

- Economies of scale show that companies with efficient and high production capacity can lower their costs, but this is not always the case.

- Thus, the above are some benefits that the procedure of marginal cost analysis contributes to the entire manufacturing process.

- It provides guidance regarding decision-making for the management in terms of pricing, allocation of resources, planning or production quantity, sales target, profit target, etc.

- By navigating these complexities, businesses can make informed decisions that optimize resource allocation.

- In contrast, fixed costs, like rent and overhead, remain constant and are not considered when evaluating incremental costs since they don’t fluctuate with production volumes.

Profitable business decisions Accounting for Technology Companies include knowing when is the best opportunity to produce more goods and sell at a lower price. While measuring incremental costs is crucial for making informed business decisions, the process is fraught with challenges that require careful consideration and a nuanced approach. Businesses must navigate these challenges with a combination of empirical data, sound judgment, and an understanding of the broader economic context in which they operate. The long-run incremental cost for lithium, nickel, cobalt, and graphite as critical raw materials for making electric vehicles are a good example.

- Costs are determined differently by each organization according to its overhead cost structure.

- Incremental cost analysis can help companies identify the optimal point at which economies of scale are realized and maximize profitability by producing at that level.

- If the incremental revenue earned from producing or selling these additional units is greater than their incremental costs, then it’s a profitable decision for the company.

- Remember, incremental cost isn’t just about numbers; it’s about optimizing outcomes and shaping a better future.

- This is the increase/decrease in the cost of producing one more additional unit or serving one more additional customer.

Effective Inventory Management: Strategies for Maintaining Optimal Minimum Stock Levels

The reason why there’s a lower incremental cost per unit is due to certain costs, such as fixed costs remaining constant. Although a portion of fixed costs can increase as production increases, the cost per unit usually declines since the company isn’t buying additional equipment or fixed costs to produce the added volume. Remember that incremental variable costs are essential for informed decision-making.

Incremental Cost: Definition, How to Calculate, and Examples

For example, producing even one extra widget would cause a tiny bit extra wear and tear on the machine. In summary, understanding the concept of output or activity level is essential for businesses to analyze costs, make informed decisions, and optimize their operations. By considering various perspectives and utilizing examples, we can gain a comprehensive understanding of how output or activity level impacts incremental costing. In the realm of business decision-making, understanding incremental cost is akin to wielding a powerful tool. It allows organizations to dissect the impact of changes in output or input on their overall cost structure.

- It has lowered as some of your fixed costs have already been covered by your normal production volume.

- For instance, if a manufacturing process uses a great deal of energy, then utility cost would be a variable cost.

- It is important to note that these costs are short-term and can be adjusted rather instantaneously to maintain a variable cost per unit graph within feasible limits.

- The fixed costs don’t usually change when incremental costs are added, meaning the cost of the equipment doesn’t fluctuate with production volumes.

- Since they are not always directly observable, businesses must often rely on estimates and indirect measurements, which can introduce a degree of uncertainty into the analysis.

- On the other hand, if incremental costs are higher than incremental revenue, the company may choose to forego production and instead purchase the product from an external supplier or discontinue it altogether.

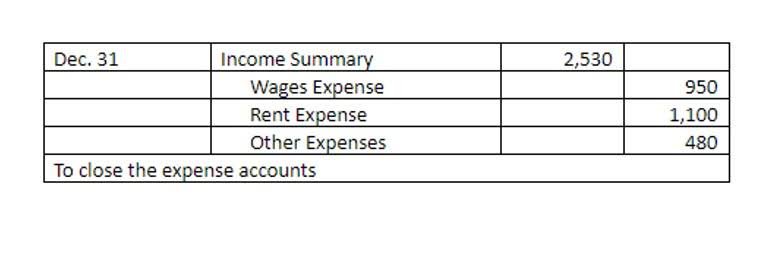

In January 2023, 5.4 percent was applicable for the blending rate for that fiscal. However, the increment in the rate to 6 percent would increase the per unit variable cost by Rs 0.226 per unit. Incremental cost is commonly computed by manufacturing companies as an aid to short-term decision making. Expanding from 10,000 units to 15,000 units, let’s assume total monthly costs increase to $120,000. For instance, evaluating incremental cost expanding monthly production from 10,000 units to 15,000 units means the incremental change is 5,000 units.

Incremental Cost Allocation Method

Marginal cost is the change in total cost as a result of producing one additional unit of output. It is usually calculated when the company produces enough output to cover fixed costs, and production is past the breakeven point where all costs going forward are variable. However, incremental cost refers to the additional cost related to the decision to increase output. In summary, understanding incremental cost is essential for businesses to make informed decisions, optimize resource allocation, and maximize profitability. By analyzing the change in costs resulting from specific changes in output or input, organizations can gain valuable insights into their operations and What is bookkeeping drive sustainable growth. When it comes to managing finances effectively, understanding incremental cost can make a significant difference.

It represents the added costs that would not exist if the extra unit was not made. That means that many fixed costs such as rent on a factory or buying a machine are not usually represented. However, if an economist wanted to be extremely precise, they might include some element of these fixed costs where they could specifically link them to the production of the extra unit.

Introduction to Incremental Costs

Businesses need to find out incremental costs to stay informed about the investment in producing extra units or providing services. It helps businesses to identify profits and losses, which is beneficial in financial management. Incremental cost analysis plays a vital role in helping businesses make informed decisions related to production, pricing, and profitability. Companies often use this analytical tool when deciding whether to increase or decrease their output based on the incremental costs involved. Variable costs, as mentioned earlier, are the only costs that directly correlate with incremental production and are included in determining incremental costs. These include labor, raw materials, and other direct expenses related to manufacturing a unit of product.